Emergency medical number: 120;

How to Apply a Bandage to a Wound

Bandages are essential tools for treating wounds. Their main purpose is to secure the dressing over the wound, immobilize fractures or bruises, and help control bleeding by applying pressure. They also serve to protect the injured area from further damage or infection.

Key Steps for Applying a Bandage

1. **Circular Method**: This is commonly used on areas like the wrist where the limb has uniform thickness. Start by wrapping the bandage in a circular manner, slightly overlapping each turn. The first loop should be angled, and subsequent loops should form a tight ring, securing the end with adhesive tape or by knotting the ends.

2. **Spiral Method**: Ideal for limbs that have similar thickness throughout. Begin with a few circular turns, then spiral the bandage upward, covering about one-third or two-thirds of the previous layer each time.

3. **Spiral Reverse Method**: Used when there's a change in limb size, such as around a joint. Start with a circular wrap, then fold the bandage and cover one-third or two-thirds of the previous layer. Wrap from bottom to top, ensuring even pressure.

4. **Serpentine Method**: Best for securing splints. Begin with a few circular wraps, then alternate between diagonal and horizontal layers, using the full width of the bandage for support.

Important Precautions

1. Avoid making the bandage too tight or too loose. A tight bandage can restrict blood flow, while a loose one may not hold the dressing in place. After applying, check if the skin is warm and free of swelling.

2. In emergencies, you can use alternatives like towels, handkerchiefs, or even long socks if proper bandages are unavailable.

3. Avoid placing knots directly over the wound or on the back, as this may cause discomfort during sleep.

Effective Methods for Stopping Traumatic Bleeding

Traumatic bleeding occurs when blood vessels rupture due to external force. If the blood flows out through the skin, it’s called external hemorrhage, while internal bleeding occurs inside the body. Arterial bleeding is bright red and pulsates, venous bleeding is darker and slower, and capillary bleeding is more gradual and easier to manage.

In most cases of minor external bleeding, applying direct pressure and using a sterile dressing can stop the flow. For severe limb injuries, a tourniquet may be necessary.

Common Hemostatic Techniques

1. **Digital Pressure (Shiatsu)**: Apply direct pressure to the wound or press on the artery above the injury. This method works well for surface wounds and limbs.

2. **Pressure Dressing**: Use a thick sterile dressing on the wound and apply a bandage to maintain pressure. In some areas, like the armpit or groin, bending the limb can also help control bleeding.

3. **Tourniquet Application**: Used for severe bleeding when other methods fail. A flexible rubber band is ideal, but in an emergency, cloth or clothing can be used. Place the tourniquet about 5 cm above the wound, wrap it tightly, and ensure the bleeding stops. However, avoid using wires or metal objects.

When using a tourniquet, monitor the limb for signs of poor circulation, such as coldness or paleness. It should only be used as a last resort and removed as soon as possible after reaching medical care. Always mark the time of application and relax the tourniquet periodically if needed.

Remember, correct application of bandages and hemostasis techniques can save lives in critical situations. Always stay calm and follow the steps carefully to ensure the best outcome.

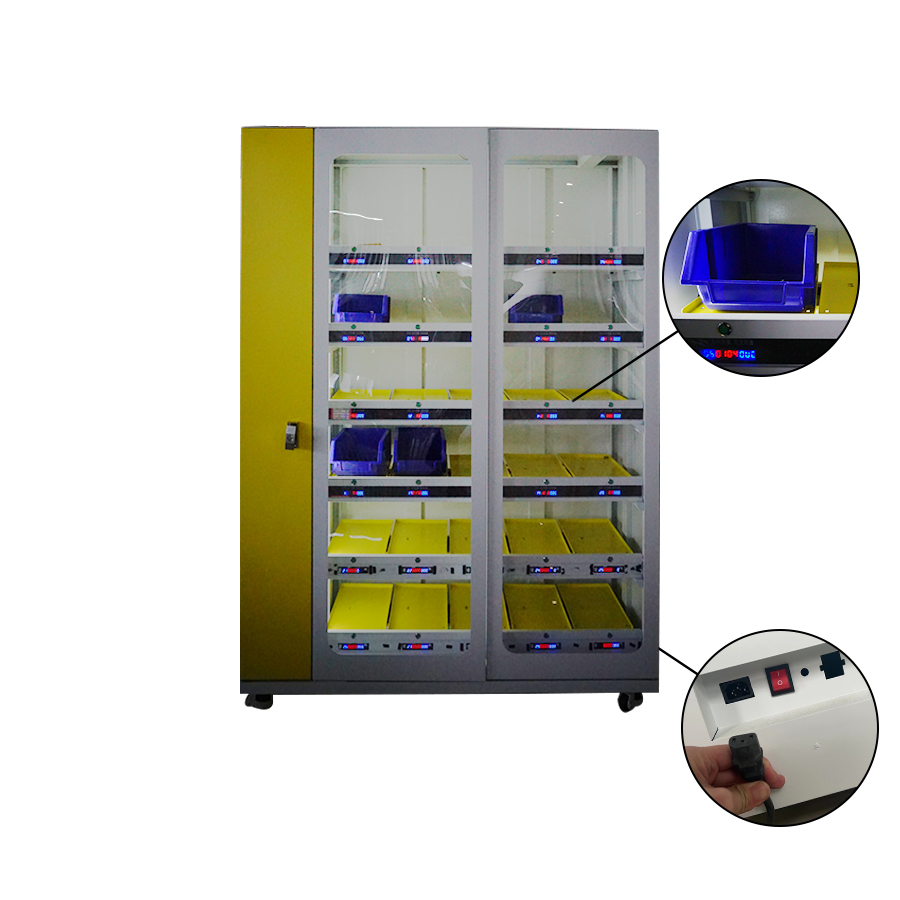

tool tracking, hazardous materials, precision weighing

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com